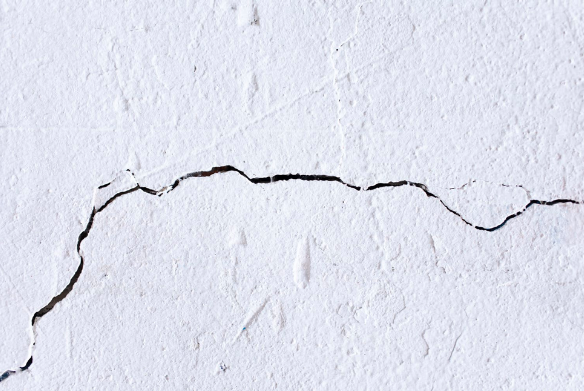

Cracks arising during construction are a common issue. When a building component’s strength is stressed beyond its capacity, fractures begin to appear. There are numerous outside elements that can cause cracks in the structure of a building, including landslips, earthquakes, chemical reactions, temperature changes, shrinkage, and poor construction practices. Cracks compromise the building’s structural integrity, aesthetic appeal, safety, and even its long-term endurance.

It is essential to be vigilant about the structural integrity of your building and understand how external factors can affect it, which is why hiring a vibration analysis consultant can protect you from unforeseen losses and guide you towards profitable prospects.

There are many ways the structural integrity of a building can be measured using different devices. Seismographs, displacement gauges, strain gauges, and accelerometers are all used to monitor vibrations. They can be used for extensive data to help you evaluate the situations of a building before and after construction.

Using a manual crack monitor is the traditional way to measure cracks. An engineer interprets vibrations of the crack in the building once the monitor is placed across a fracture. However, proper analysis requires frequent site inspections and meticulous note-taking.

Nowadays, engineers have started utilizing digital crack monitors. These monitors can be connected to data acquisition systems for wireless monitoring and keep recording vibrations to alert you in case of any significant changes. In order to show how a fracture changes when a structure naturally heats and cools, the sensors frequently measure temperatures simultaneously. For quick and thorough examination, data is often shown on a cloud service at an hourly rate.

The digital crack monitor can and should be in position for several months to years to gather as much evidence as possible and determine whether or not the movement is still occurring and in which direction. In order to eliminate the requirement for site inspections, these digital monitors can operate on batteries for many years.

We at G3 SoilWorks offer consultation for the installation of crack monitors that can measure the radial, transverse, and vertical acceleration of the ground as well as the sound pressure levels. These measurements provide crucial information for any development, monitoring, and construction project.

Contact us and maximize the productivity and profitability of your projects in Southern California by supporting them with our geotechnical and geological experience.

Follow, engage, learn. Stop by our blog to see what’s happening at G3SoilWorks.

G3Soilworks – a full service geotechnical/ engineering geologic consulting firm serving clients since 2009 and delivering expert solutions with our highly experienced team and specialized consultants.

G3SoilWorks

350 Fischer Avenue Costa Mesa, CA 92626

Tel. 714.668.5600

E. info@g3soilworks.com